Screen printing exposure units are an essential part of the screen-printing process. They are used to expose the image onto the screen, making it ready for printing. There are several different types of exposure units available, each with their own unique features, benefits, and disadvantages.

In this blog we will cover the most popular types of exposure lights and styles of exposure units used to create a screen-printing stencil.

First let's discuss the light sources that can be used:

- UV LED Exposure Units

- Metal Halide Exposure Units

- Conventional White Light Exposure Units

- Fluorescent Tube Exposure Unit

- UV LED Exposure Unit

UV LED exposure units use light-emitting diodes (LEDs) to expose the image onto the screen and ultraviolet light to expose the image onto the screen. This type of unit is known for its ability to produce high-quality prints with sharp details. UV exposure units can also be used to expose larger screens, making them ideal for large-scale printing projects. This type of unit is energy efficient and produces less heat compared to other types of exposure units. LED exposure units are also known for their quick exposure times and consistent exposure quality. LED exposure units take many shapes and forms, some look like a vacuum exposure unit, with a light that beams up onto the print. Other units the light is suspended above the print.

Advantages of an UV LED Exposure Unit:

- Energy Efficiency: LED light use less energy compared to other types of exposure units, which can reduce operating costs and minimize the environmental impact of screen printing. UV light produces high-quality prints with sharp details. This is particularly important for high-detail images that require precise exposure to achieve the desired results.

- Quick Exposure Times: LED exposure units typically have quick exposure times, which can speed up the overall screen-printing process.

- Consistent Exposure Quality: LED exposure unit lights are known for their consistent exposure quality, which can result in sharper and more accurate prints.

- Long-lasting: LED and UV light have a long lifespan and are durable, making UV LED exposure units a reliable option for screen printers.

Disadvantages of an UV LED Exposure Unit:

- Wide range in cost: UV LED exposure unit price points vary dependent on the number of lights within the unit, the more lights that are included, the more expensive. However, Screen Print Direct has developed a budget friendly UV LED exposure unit that will not break the bank! Starting at $68.99

- UV Light Hazards: UV light can be hazardous to the eyes and skin, and precautions should be taken when using a UV exposure unit.

In conclusion, UV LED exposure units offer many benefits for screen printers looking for a fast and efficient exposure solution. However, the higher cost, maintenance and UV safety hazards should be considered. Ultimately, the choice of an UV LED exposure unit will depend on the specific needs and budget of the user.

- Metal Halide Exposure Unit

Metal halide exposure units use metal halide lamps to produce ultraviolet light. This type of unit is known for its fast exposure times and high-quality results. However, metal halide exposure units are also more expensive compared to other types of exposure units.

Benefits of a Metal Halide Exposure Unit:

- High-Intensity Light: Metal halide lamps provide a high-intensity light that results in sharp and accurate prints.

- Large Screen Capabilities: Metal halide exposure units can be used to expose larger screens, making them ideal for large-scale printing projects.

Disadvantages of a Metal Halide Exposure Unit:

- Long Warm-Up Time: Metal halide lamps require a warm-up time before they reach their maximum brightness, which can slow down the overall screen-printing process.

- Short Life Span: The metal halide lamp used in a metal halide exposure unit has about 500 hours of use before the light begins to dim. When this happens, the light source because less effective and will need to be replaced.

- Heat Generation: Metal halide lamps generate a significant amount of heat, which can cause issues with the exposure unit and the surrounding environment.

- Large Energy Consumption: With these exposure units the power is never truly off, instead it goes on standby. When in standby mode the unit uses a substantial amount of power, almost equivalent to the amount of power the unit uses when fully powered on. T

In conclusion, metal halide exposure units offer many benefits for screen printers looking for a high-quality and efficient exposure solution. However, the long warm-up time and heat generation may be a concern for some users. Ultimately, the choice of a metal halide exposure unit will depend on the specific needs and budget of the user.

- Conventional White Light Exposure Unit

Conventional White Light Exposure Unit: Conventional white light exposure units use a light bulb or light source to expose the image onto the screen. This type of unit is typically the least expensive option, but it may not produce the same level of quality as other types of exposure units. Typically, we see printers use 500w Halogen bulbs for this type of exposure unit. This unit can be a DIY construct as all you really need it a light bulb.

Benefits of a Conventional White Light Exposure Unit:

- Cost-effective: Conventional exposure units are typically less expensive compared to other types of exposure units, making them a good option for screen printers with limited budgets.

- Easy to Use: Conventional exposure units are easy to use and typically require little to no setup time.

- Large Screen Capabilities: Conventional exposure units can be used to expose larger screens by adding more light bulbs, making them ideal for large-scale printing projects.

Disadvantages of a Conventional White Light Exposure Unit:

- Inconsistent Exposure Quality: The quality of the exposure may vary depending on the light source used, which can result in inconsistent exposure quality.

- Long Exposure Times: Conventional white light exposure units typically have longer exposure times compared to other types of exposure units, which can slow down the overall screen-printing process.

Conventional white light exposure units offer a cost-effective and easy-to-use option for screen printers. However, the inconsistent exposure quality and longer exposure times may be a concern for some users. Ultimately, the choice of a conventional exposure unit will depend on the specific needs and budget of the user.

- Fluorescent Tube Exposure Unit

This is a common yet ineffective type of screen-printing exposure unit. This unit is comprised of fluorescent light tubes that are used to burn an image into a screen-printing frame. The light tubes can be either black or white light.

Benefits of Fluorescent Tube Exposure Units:

- Cost-effective: Fluorescent tube exposure units are generally less expensive than other types of exposure units, making them a popular choice for screen printing businesses on a budget.

- Easy to use: These units are simple to set up and use. Once the screen is properly prepared and positioned, exposing the design is as simple as turning on the unit and waiting for the exposure time to complete.

- Long-lasting bulbs: Fluorescent tubes can last for thousands of hours, which means they may not need to be replaced as frequently as other types of bulbs.

Disadvantages of Fluorescent Tube Exposure Units

- Limited UV output: Compared to other types of exposure units, fluorescent tube units may not output as much UV light, which can result in longer exposure times and/or less precise designs.

- Limited size options: Fluorescent tube exposure units may not be available in as many size options as other types of units, which can limit the screen sizes that can be used.

We do not advise using this type of exposure unit. Due to the weakness of the light, it will take a long time to expose your screen. This type of light is also not safe to use daily. There are better exposure light options that are inexpensive compared to Fluorescent Tube Exposure Units.

Now lets talk about the style of exposure unit:

There are several different styles of exposure unit you can use for screen printing. The style of unit can have many different light source types inside, we discussed the light source type heavily above. Here we will point out the differences in the build of the exposure unit.

- Vacuum Exposure Unit

- Latch Lid Exposure Unit

- Light Suspended Above Exposure Unit

- Table Exposure Unit

Within these types of builds, some units can be a combination of the two. For example, a vacuum exposure unit can be a cabinet style.

Vacuum Exposure Unit: This type of exposure unit uses vacuum pressure to hold the screen in place while the image is being exposed. This ensures that the screen remains flat and consistent throughout the exposure process, resulting in a sharp and accurate print. This is the most expensive type of unit.

Pictured above: Vacuum Exposure Unit for Table

Latch Lid Exposure Unit: This type of unit is simple; the lid closes over the unit and latches shut. It is very similar to the vacuum exposure unit, however, isn’t as good because the vacuum exposure unit ensures better contact between the screen and the glass. This unit is cheaper than a vacuum unit and will get the job done.

Pictured Above: Latch Lid Exposure unit for Table

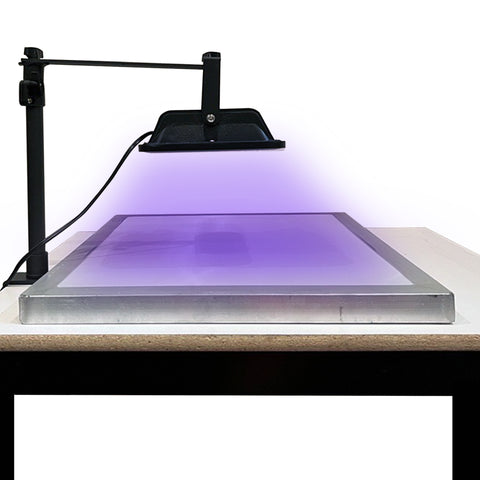

A unit built with the light suspended over the frame: This unit just requires the light to be focused on the print area, it is done by suspending the light approx. 18inches away from the screen. This type of unit doesn't provide the same accuracy as units mentioned above but will get the job done effectively. This unit does take a bit longer to expose than those mentioned above. This unit can be constructed as a DIY project.

As mentioned above, Screen Print Direct has developed budget friendly LED exposure unit that is simple to set up and use. Our new exposure unit starts at $68.99 and is the perfect solution for printers getting their feet wet in screen printing.

Screen Print Direct's UV LED Exposure Unit - Example of light suspended above screen

Table exposure unit: This is a very common type of exposure unit; it is called a table exposure unit because it sits on a table or a flat surface. With this type of unit, the light is very close to the artwork being burned into the screen. While this might seem like an advantage to have to light burning so closely to the image, it doesn’t produce the crispest image. When the light is so close to the image, the light bounces off the contact point causing small fractures in the light, this can give a slight blue to the burn. This slight burn is very minimal and for everyday t shirt printing isn’t noticeable. The two units pictured above are also considered table units.

Cabinet Exposure unit: This type of unit is larger than a table unit and can take up quite a lot of floor space. This unit is large because the light source is approx. 4 feet away from the image being burned (this distance will vary from unit to unit.) This type of unit creates a crisper image as the light isn’t fractured right away when hitting the design being burned onto the screen. The light flows more evenly onto the design giving you a nice sharp burn into the screen.

Pictured above: Metal Halide Cabinet Exposure Unit

In conclusion, the type of screen-printing exposure unit you choose will depend on your specific needs and budget. Consider the size of your projects, the level of detail required, and the speed at which you need to complete your work when selecting an exposure unit. No matter what type of exposure unit you choose, investing in a quality unit will help to ensure that your screen-printing projects are successful and profitable.

Questions or comments? Drop a note below, we love to talk all things screen printing.

Happy Printing,

The SPD Crew